WaterJet Technology

|

||||

|

History

In the 1950s, forestry engineer Norman Franz experimented

with an early form of water jet cutter to cut

lumber.

However, the technology did not advance notably until the

1970s when

Mohamed Hashish

created a technique to add abrasives to the water jet

cutter. This and other concepts allowed

Yih-Ho Michael Pao

to develop commercial "ultrahigh-pressure WaterJets and

abrasive-WaterJets into better tools for industrial cutting,

drilling, and milling, especially for the flexible factory

automation." Today the water jet is unparalleled in many

aspects of cutting and has changed the way many products are

manufactured. Many types of water jets exist today,

including plain water jets, abrasive water jets, percussive

water jets,

cavitation

jets and hybrid jets.

Operation

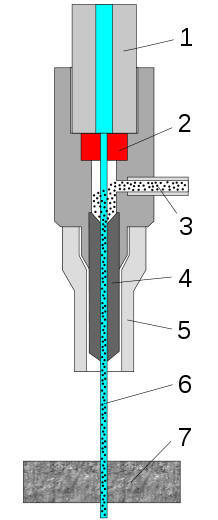

The cutter is commonly connected to a high-pressure

water pump where the water is then ejected from the nozzle,

cutting through the material by spraying it with the jet of

high-speed water. Additives in the form of suspended grit or

other abrasives, such as

garnet

and

aluminum oxide,

can assist in this process. |

||||

A diagram of a water jet cutter: |

||||

More |

||||

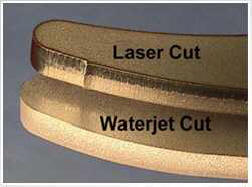

| In addition to no heat-affected

zone, the benefits and applications for WaterJet technology

are limitless and ever-expanding. In comparison to other

cutting technologies: |

||||

| WaterJet | Plasma | Laser | EDM | |

| Process | Erosion

process: high speed liquid sandpaper |

Burning /

melting process using high temperature ionized gas arc |

Melting

process using concentrated laser light beam |

Erosion

process using electrical discharge |

| Materials |

Any material. |

Primarily steel, |

Primarily steel, stainless and aluminum. Can also cut a variety of other materials. |

Conductive |

| Thickness |

Up to 24 inches, Z constraint |

Up to 2-3

inches, depending on material. |

Generally 1 inch |

Generally 12 |

|

Part Accuracy |

Up to .001" |

Up to .010" |

Up to .001" |

Up to .0001" |

|

Machine Setup |

Same setup |

Same setup |

Different |

Different wire types for different jobs |

|

As the grid above illustrates - WaterJet cutting technology has clear advantages over other cutting methods. |

||||